UV Technology

UV Technology

Safe and Chemical-Free Disinfection with Ultraviolet (UV) Water Purification Systems

BNREO UV Technology, prioritizes human health with a sustainable environmental approach and offers highly efficient and environmentally friendly water disinfection solutions. Ultraviolet water purification systems are one of the most effective and safe methods of sterilizing water without the use of chemicals. These systems eliminate pathogenic microorganisms in water using direct UV rays, ensuring hygienic water supply.

Working Principle of UV Device

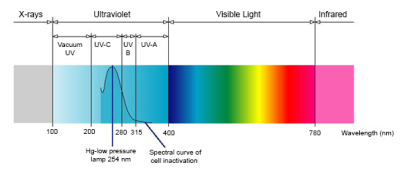

Ultraviolet devices produce ultraviolet light with a wavelength of 254 nanometers thanks to specialized UV lamps inside them. This wavelength damages the DNA and RNA structures of bacteria, viruses, fungi, and other microorganisms, preventing their proliferation and rendering them ineffective. This process is called "microbiological treatment." The system's operating structure consists of four main parts: a stainless steel housing, a UV lamp cover (quartz glass), a UV lamp, and a control panel. Water is exposed to UV rays as it passes through the device's stainless steel housing and exits the system in a sterile state.

One of the most important advantages of this method is that during the process no heating or chemical additives are usedThis way, the taste, odor, and mineral balance of the water are preserved. UV-disinfected water becomes healthy and safe without losing its natural composition. For the system to be effective, the water must be mechanically filtered to remove sediment and turbidity, operate at the appropriate flow rate, and be applied before final use.

Effect of UV Rays on Microorganisms

UV ışınları, hücre duvarını geçerek mikroorganizmaların genetik materyallerine etki eder. DNA/RNA yapısında bozulmaya yol açarak mikroorganizmanın çoğalmasını ve yaşamasını engeller. Böylece suda potansiyel hastalıklara yol açabilecek tüm patojenlerin %99,999 oranında etkisiz hale getirilmesi sağlanır.

Effect of UV rays on microorganisms;

Areas of Use

UV technology is widely used in a wide range of industries. It is particularly preferred in processes where chemical residues are not permitted:

Food and beverage industry: In production lines requiring hygiene

Cosmetics industry: For the safe production of water-based ingredients

Pharmaceutical industry: Sterile water requirement in dialysis machines and formulations

Natural spring water and mineral water bottling facilities

Before membrane systems: To prevent bacterial growth

After activated carbon filters and ion exchange systems: To prevent bacterial proliferation

Hot water systems: For bacterial control in thermal environments

Against chlorine-resistant parasites: For additional protection with chemical chlorination

Wastewater treatment plants: For safe disinfection before reuse